Biofuel

Deployment of cryogen-free compact NMR in Biofuel Plants

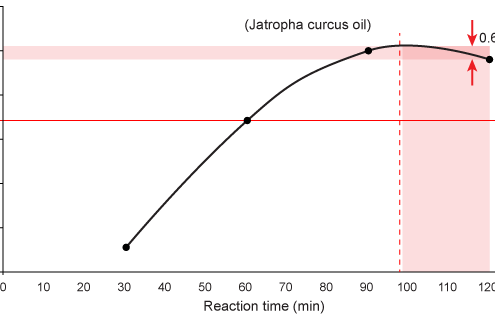

HTS-110 cryogen-free NMR systems are robust and compact, making it possible to use them for in-line reaction monitoring. The use of natural products for biofuel production means that the composition of the input material has some variability resulting in a slight reduction in maximum yield and extended transesterification times to ensure that reactions have been completed.

Reaction times are often extended to ensure that all available feedstock has been converted which can result in a slight loss of yield. Using in-line NMR monitoring allows reactions to be curtailed at the optimal point resulting in increased plant capacity and maximisation of yield.

Using HTS-110 NMR systems allows near real-time monitoring of a reaction. When the ester content starts to decrease, the reaction process can be halted on achieving maximum yield. In a 100,000 tonne per year plant a 0.2% increase in yield equates to a gain of about 200,000 litres per year without any additional expense in materials.

While an increase in yield is attractive, even greater value is obtained from reduced reaction time. Curtailing reactions at their optimal time increases the transesterification capacity of the plant by approximately 10%. So a 100,000 tonne per year plant could generate an additional US$5,000,000 in revenue as well as related savings in energy and other unit production costs.

200MHz HTS NMR Magnet. With additional passive shielding for field sensitive applications. Axial 5 gauss line is within surface of red shielding. Configured for in-line analysis.